Zebra Mount develop mounting accessories for security cameras. Most parts are developed to work with the small modular cameras made by Axis Communications.

https://www.axis.com/sv-se/products/modular-cameras

The parts are manufactured and delivered by Materialise, which is a large, professional 3D print company. The revenue for Materlialise was €197M for 2019.

https://i.materialise.com/en

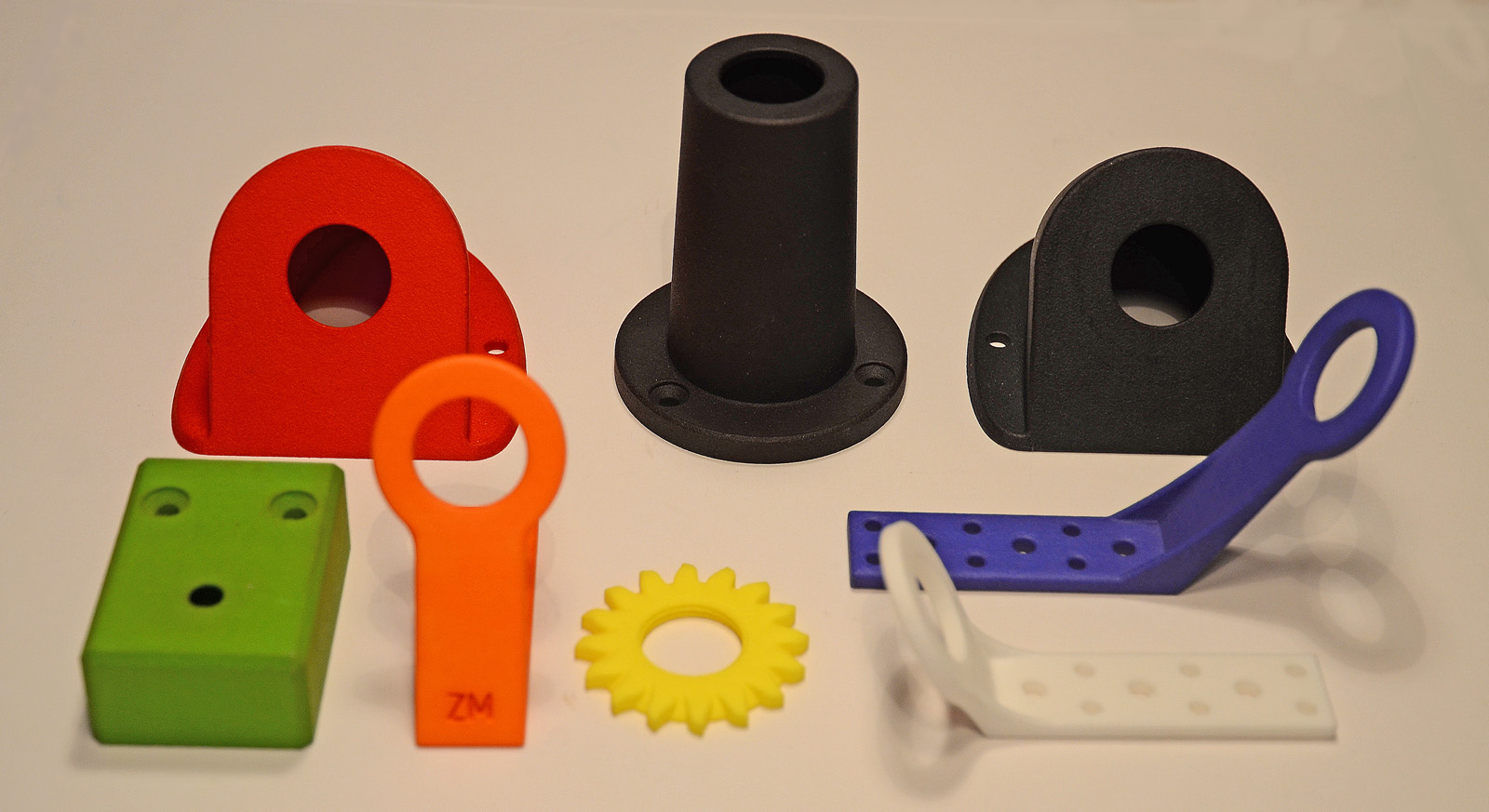

The parts are made in plastics using 3D printing in a technology called Selective Laser Sintering (SLS). It is a versatile and frequently used 3D printing technology. Basically it is a technology where a fine powder of the material is melted into parts using a laser. There is also an improved process called Multi Jet Fusion (MJF). It is similar to SLS, but it gives finer details. However it is only available in black and gray.

The material used is Polyamide, which is an exceptionally versatile, strong, and slightly flexible material. Over time, natural white Polyamide will turn slightly yellowish. It should therefore be dyed or painted. By ordering the parts in Alumide, aluminum powder is added. The parts get a silver finish that is a bit more stiff and a bit more sandy/grainy. All parts are designed for indoor use, but depending on the conditions, they may be used outdoors.

https://i.materialise.com/en/3d-printing-materials/polyamide

https://i.materialise.com/en/3d-printing-materials/polyamide-mjf

Technology

The Polyamide surface has a sandy, granular look, and is slightly porous.

The parts come out white, but should be dyed (or painted) into other colors.

These parts are made in Alumide. The mount to the right is natural (not dyed).

To view the available colors, see i.materialise's website:

https://i.materialise.com/en/3d-printing-materials/polyamide/colors-finishes

https://i.materialise.com/en/3d-printing-materials/alumide/colors-finishes